How Often Should Manual Handling Risk Assessments Be Reviewed - Ebook And Manual Free

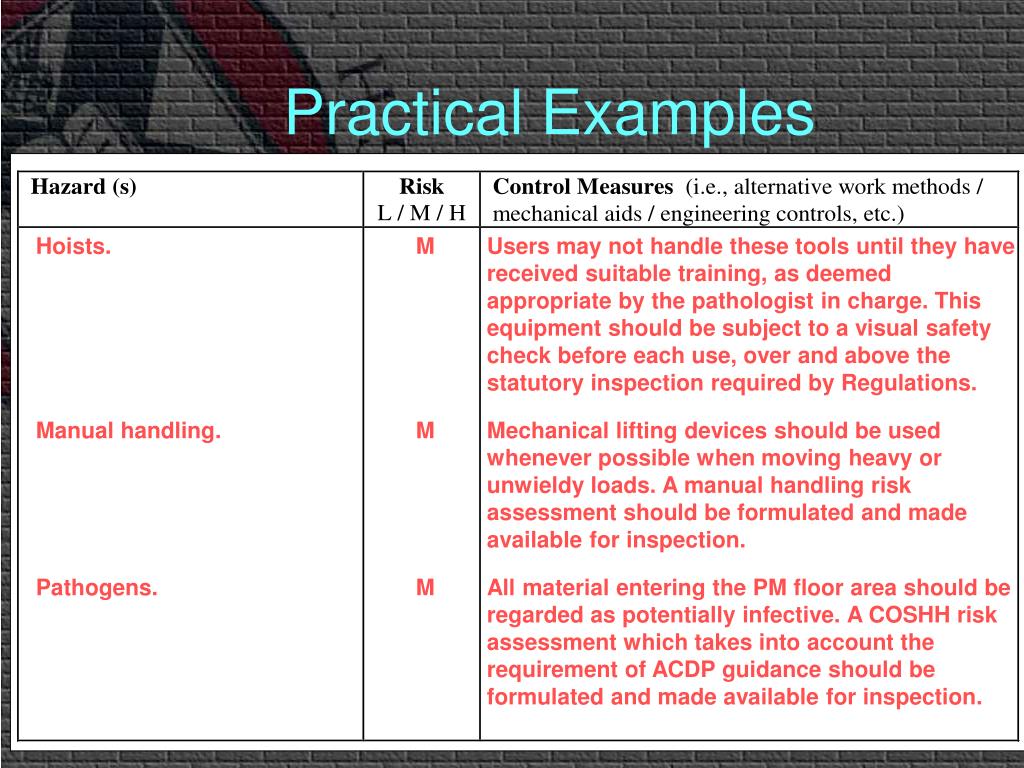

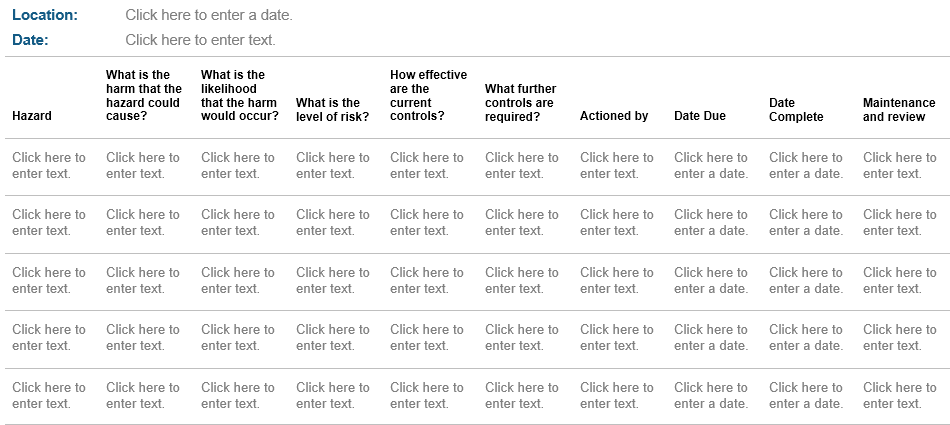

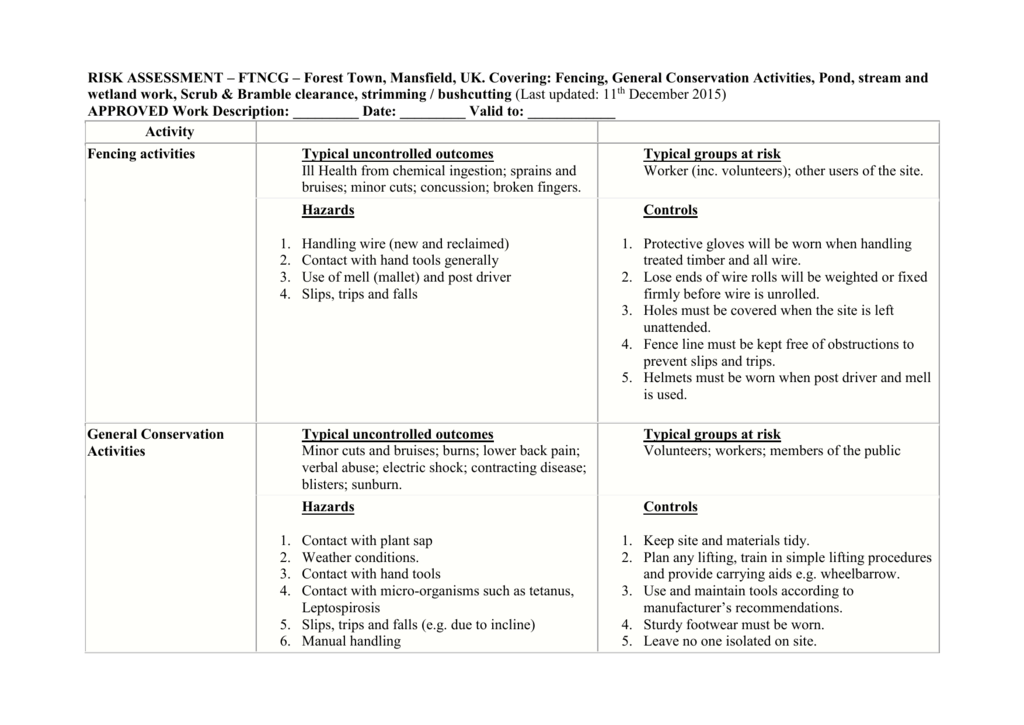

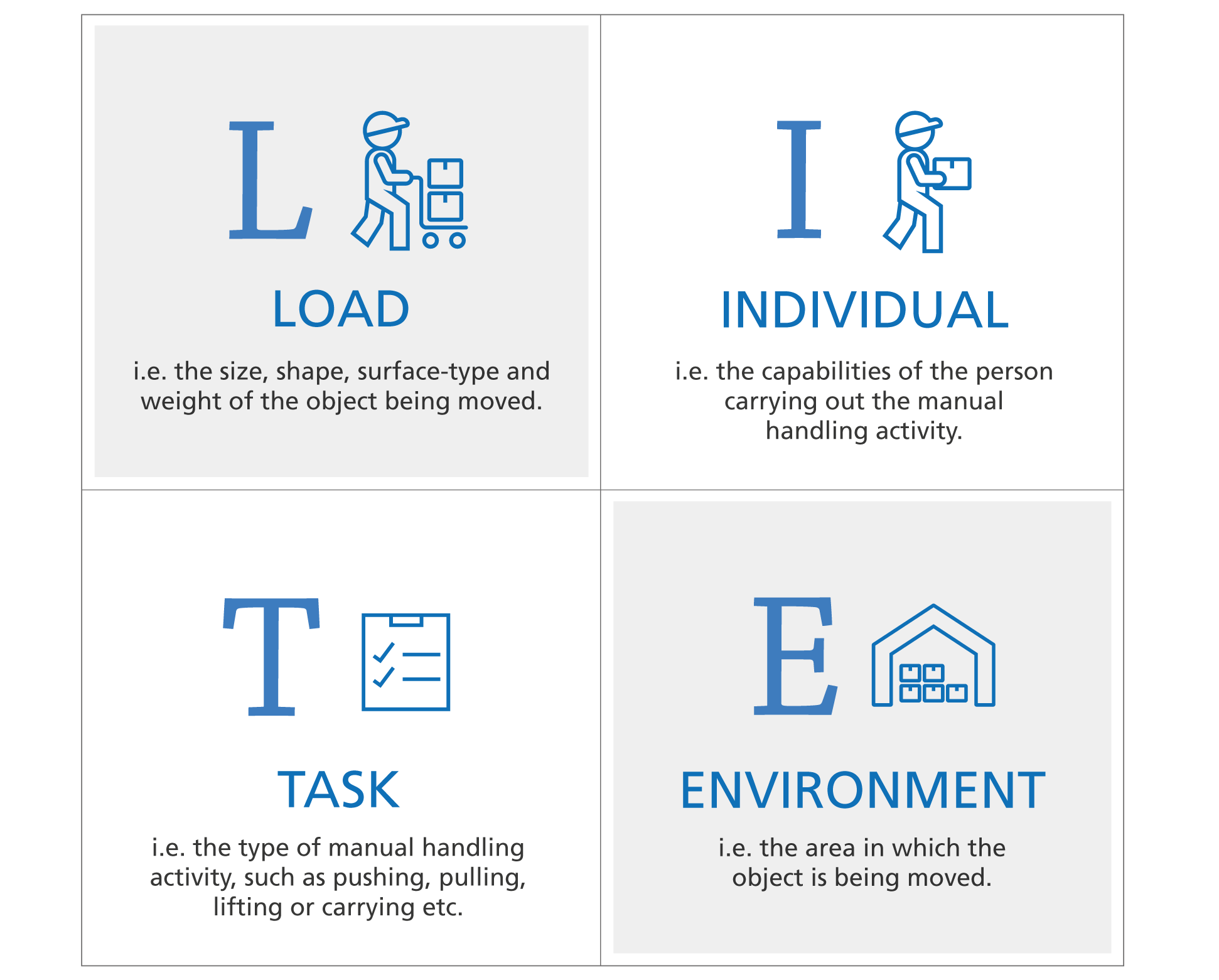

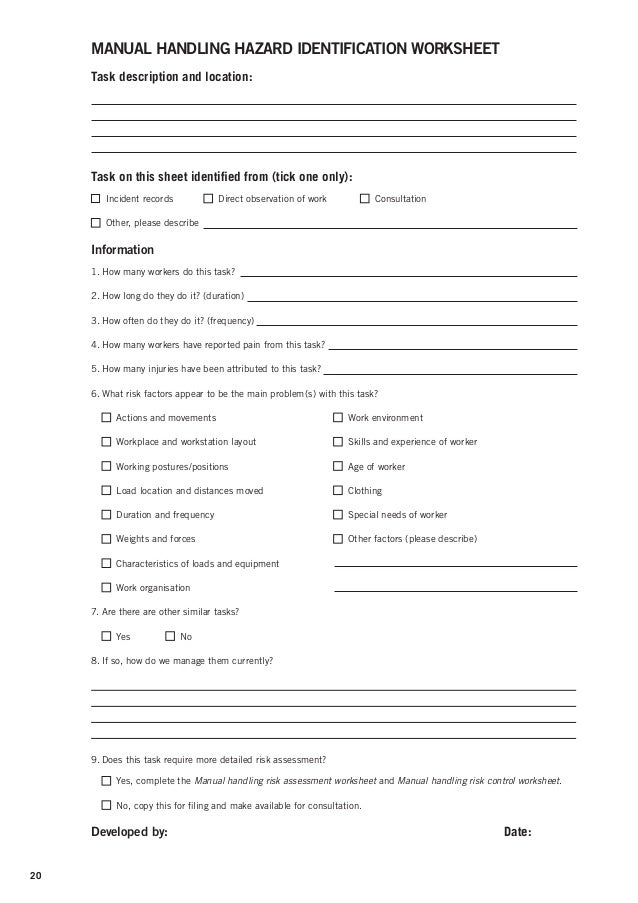

Carrying out a thorough risk assessment that includes all processes and tasks.

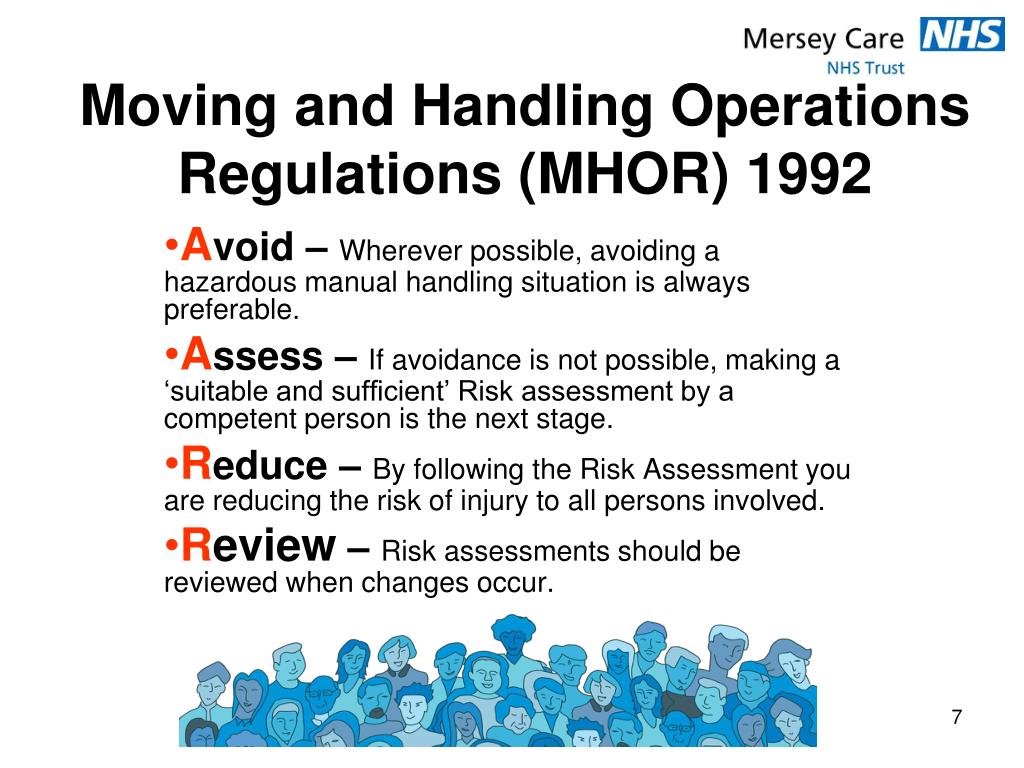

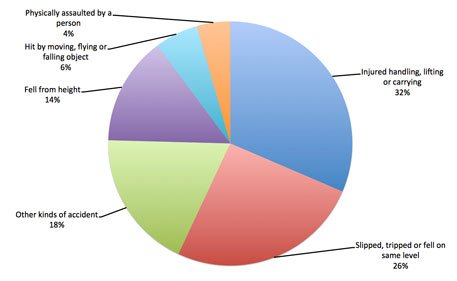

How often should manual handling risk assessments be reviewed. So it makes sense to review what you are doing on an ongoing basis look at your risk assessment again and ask yourself. It includes lifting putting down pushing pulling carrying or moving loads. Sooner or later you will bring in new equipment substances and procedures that could lead to new hazards. How often should these assessments be reviewed and who should review them.

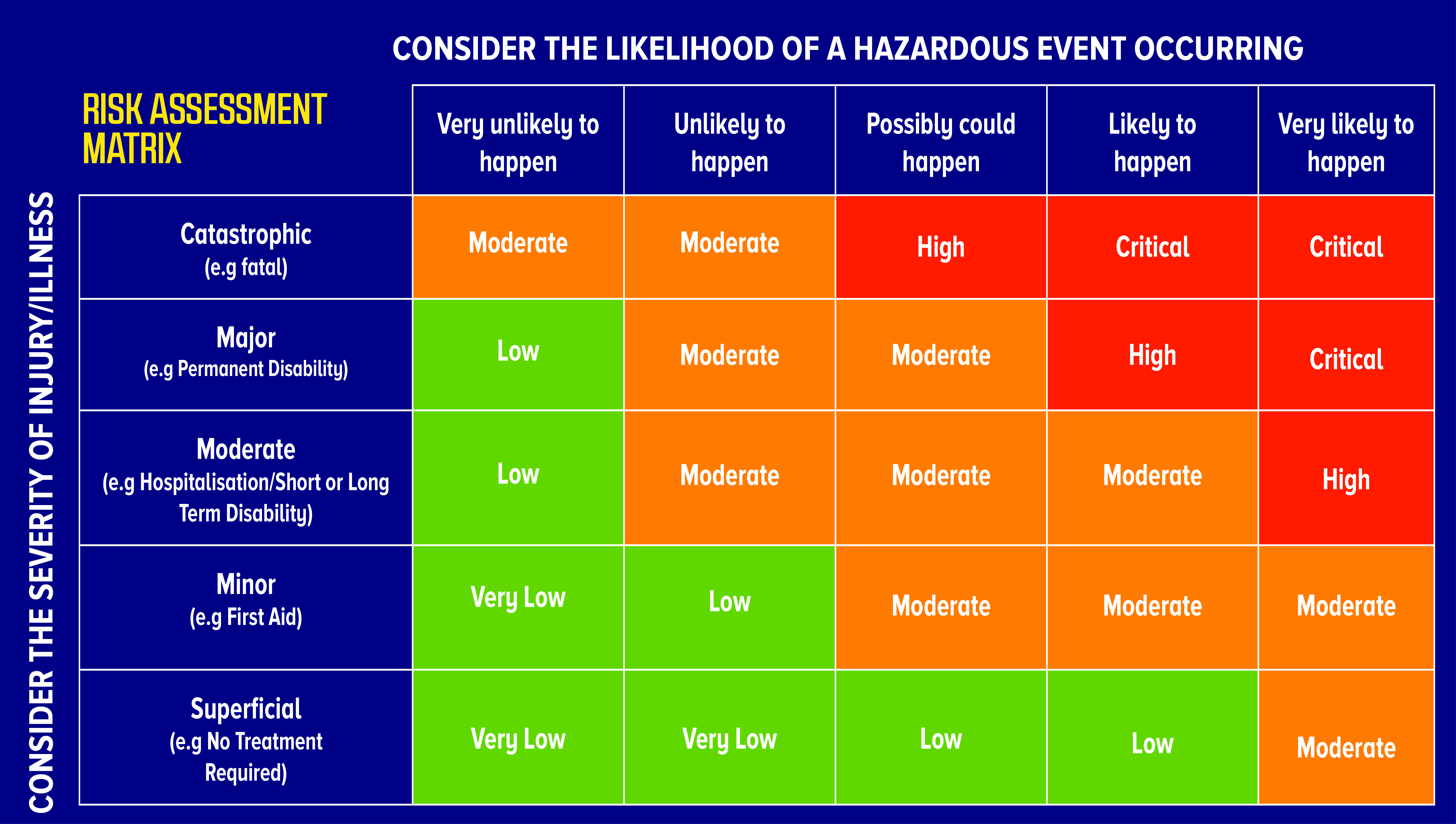

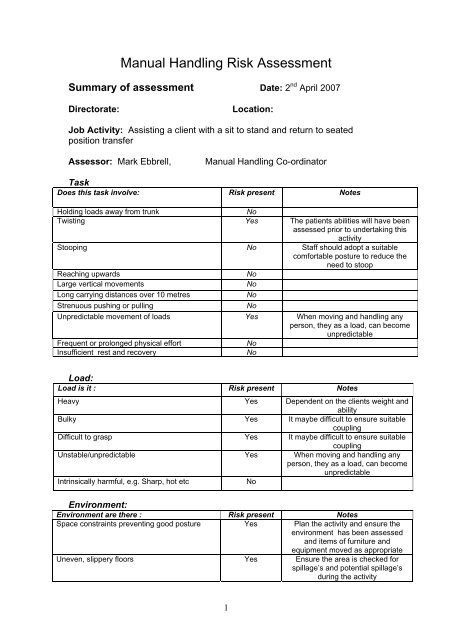

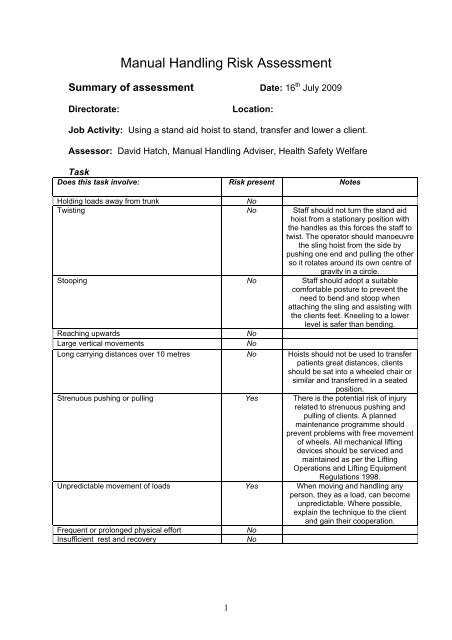

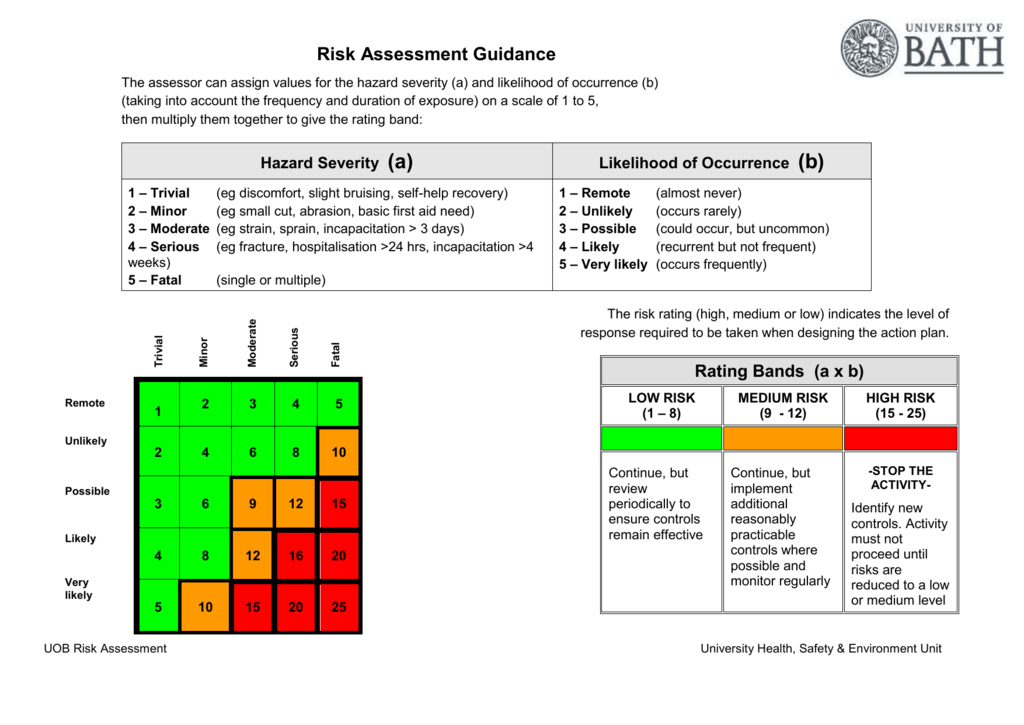

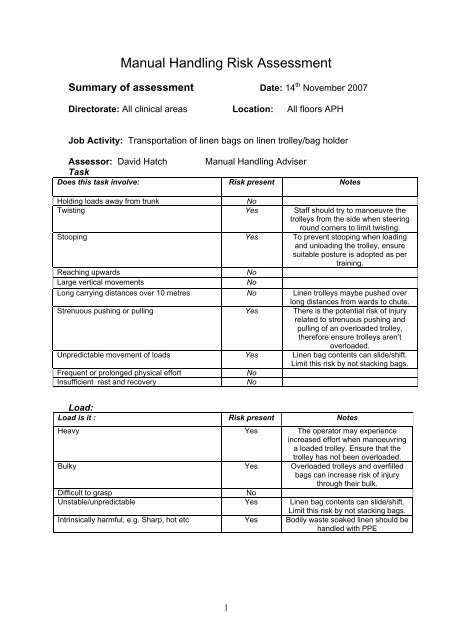

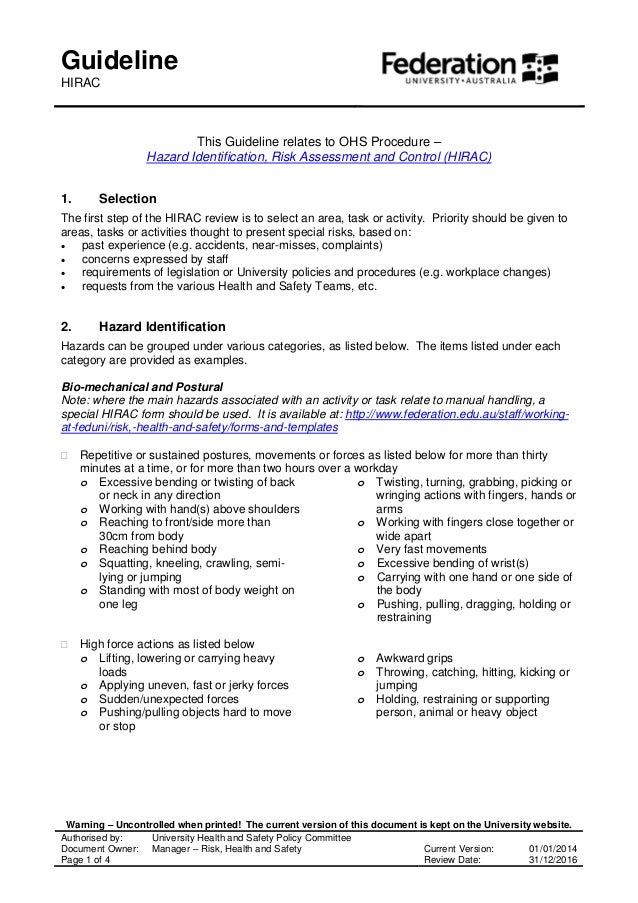

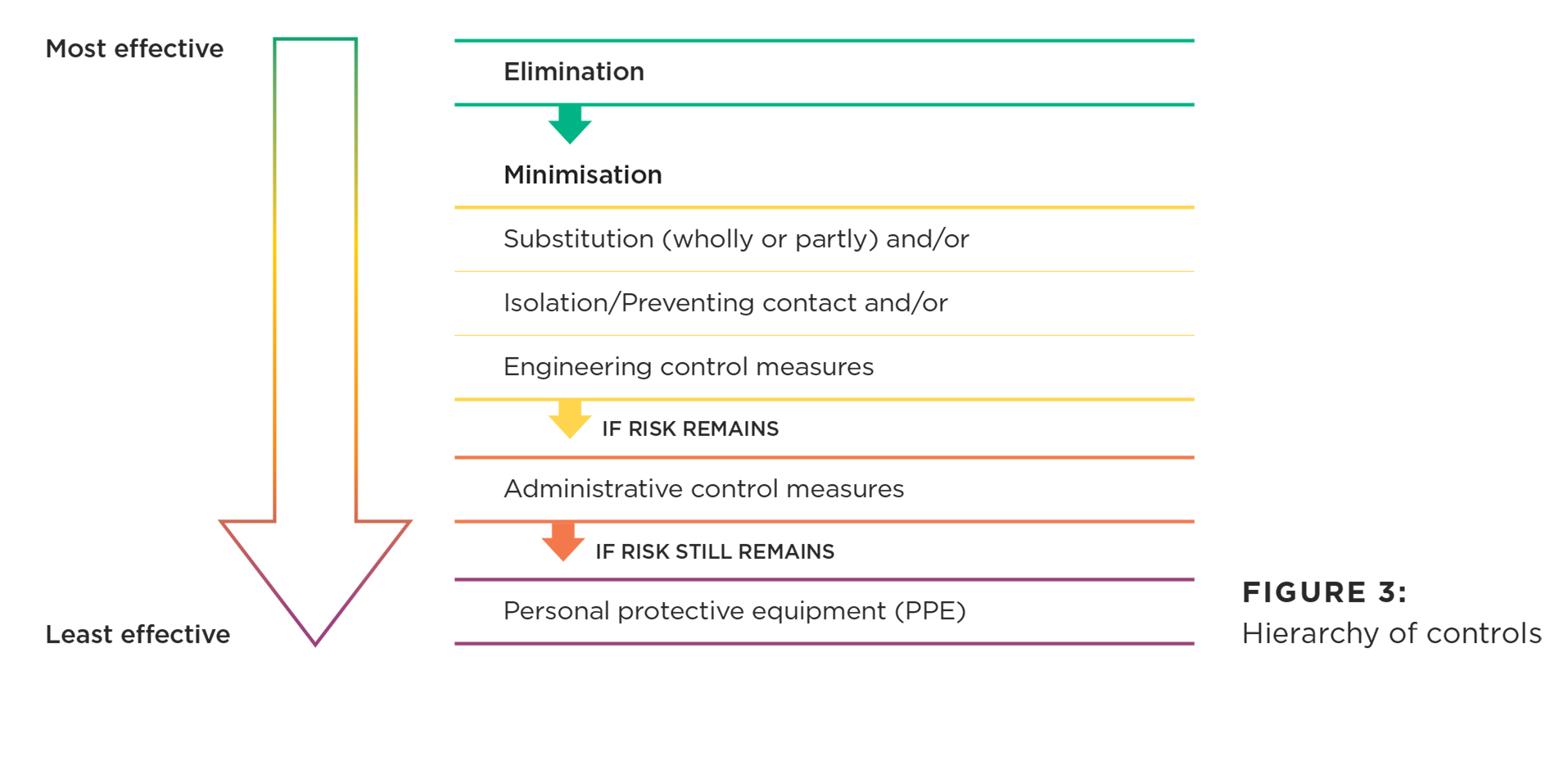

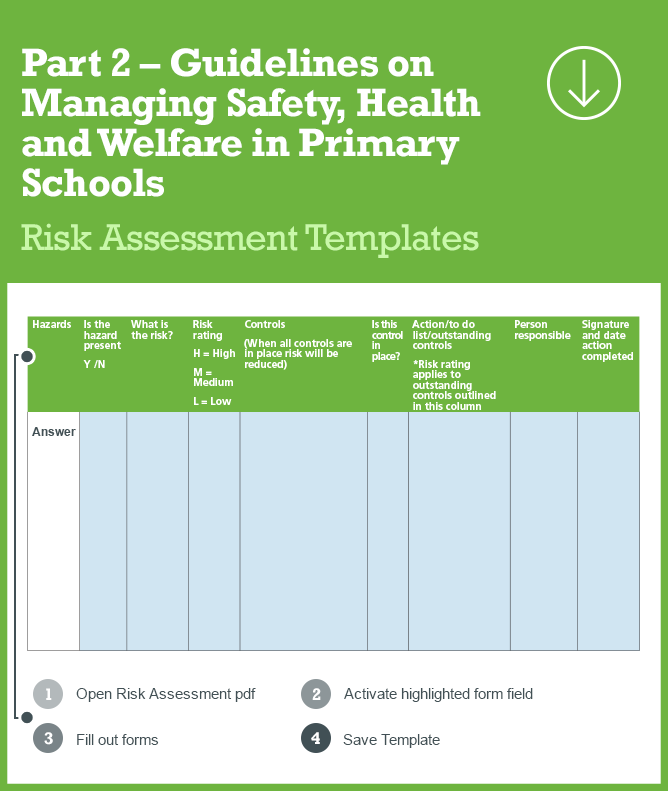

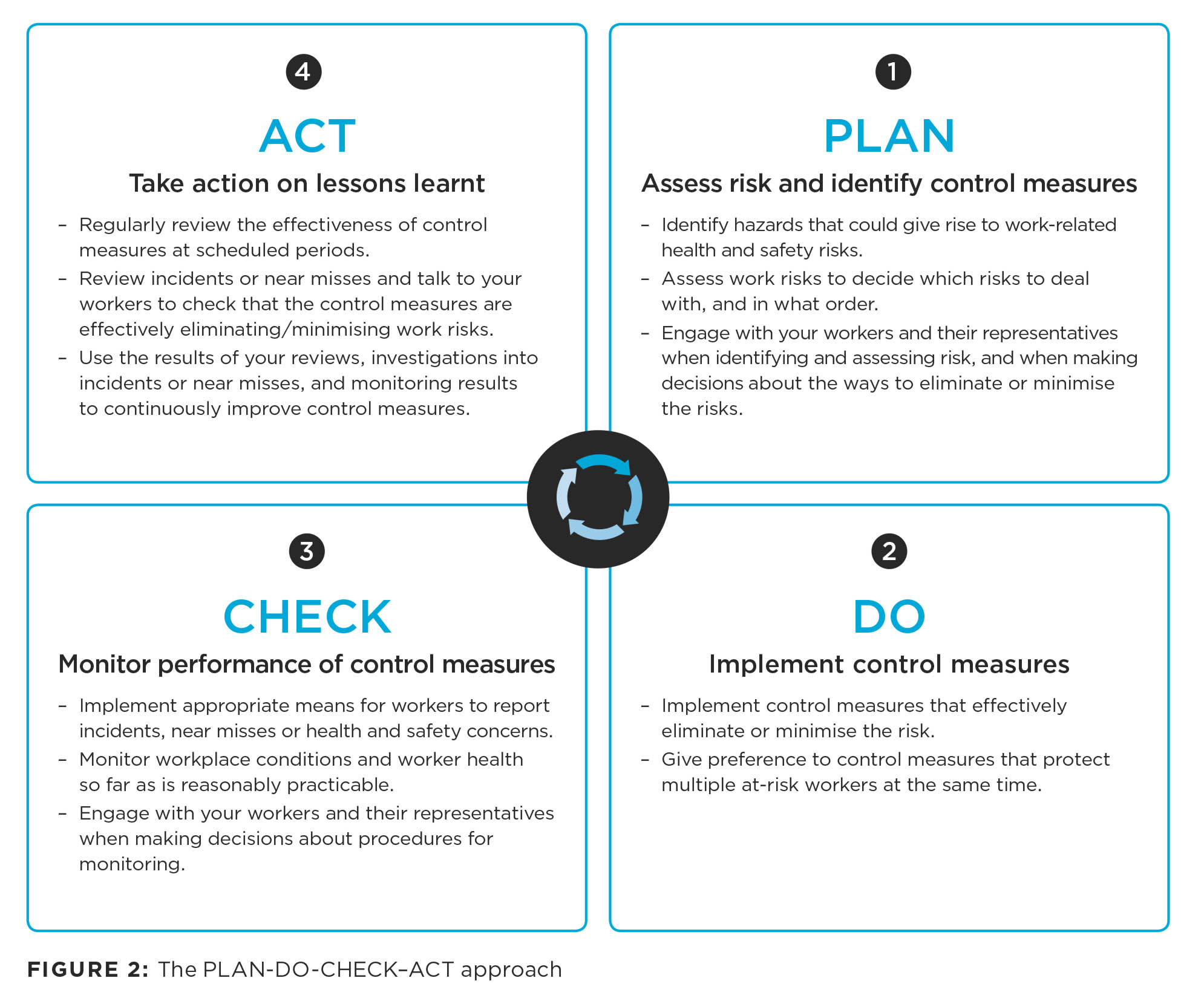

Examples of assessment checklists 4 of 21 pages section b. A risk assessment is simply a careful examination of what in your work could cause harm to people so that you can weigh up whether you have enough precautions or whether you should do more. Ensuring sufficient controls are in place to prevent any accidents. Review your risk assessment and update if necessary.

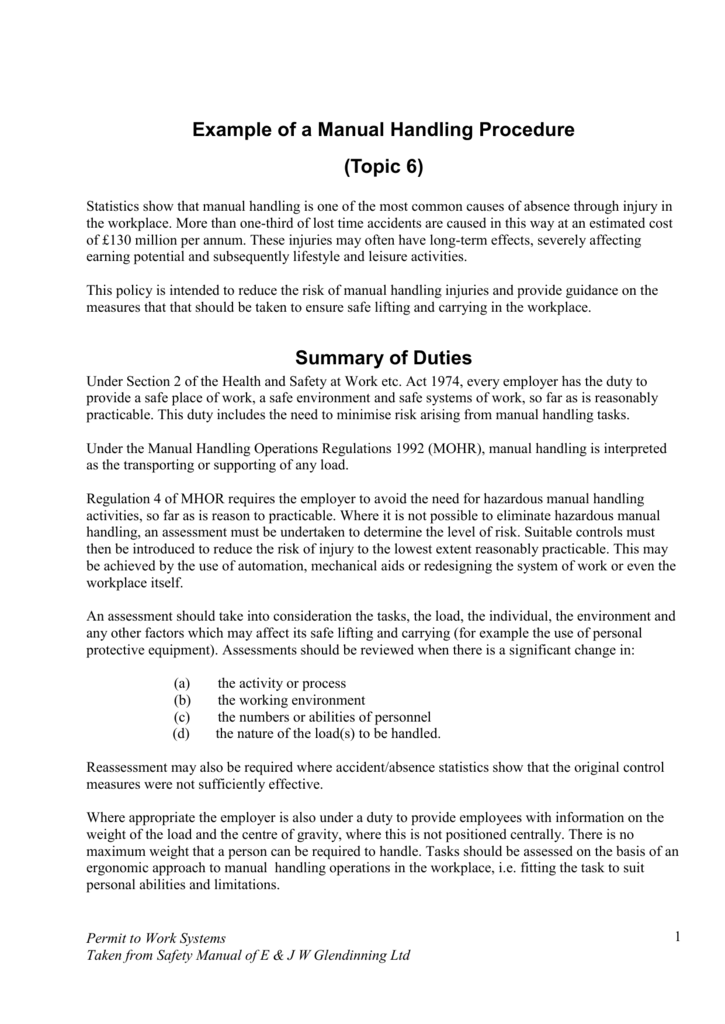

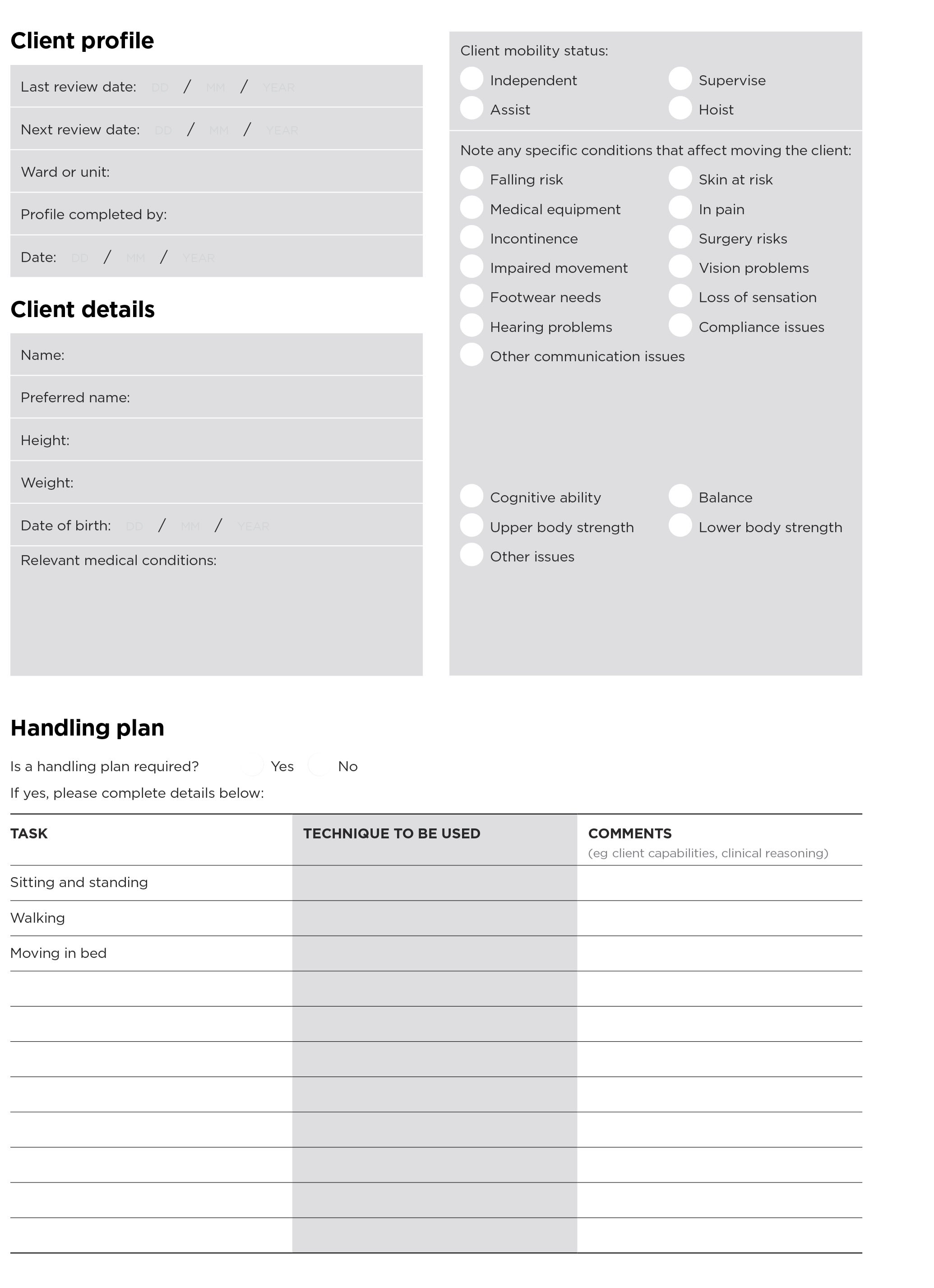

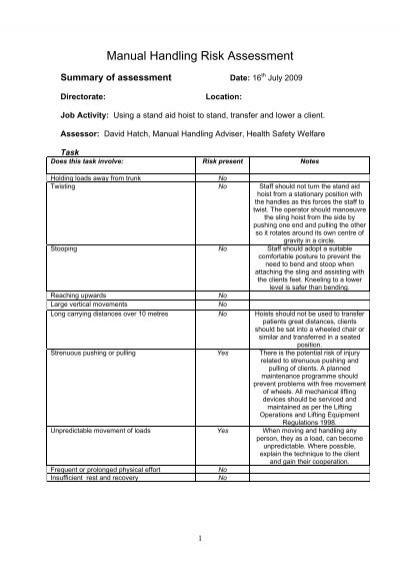

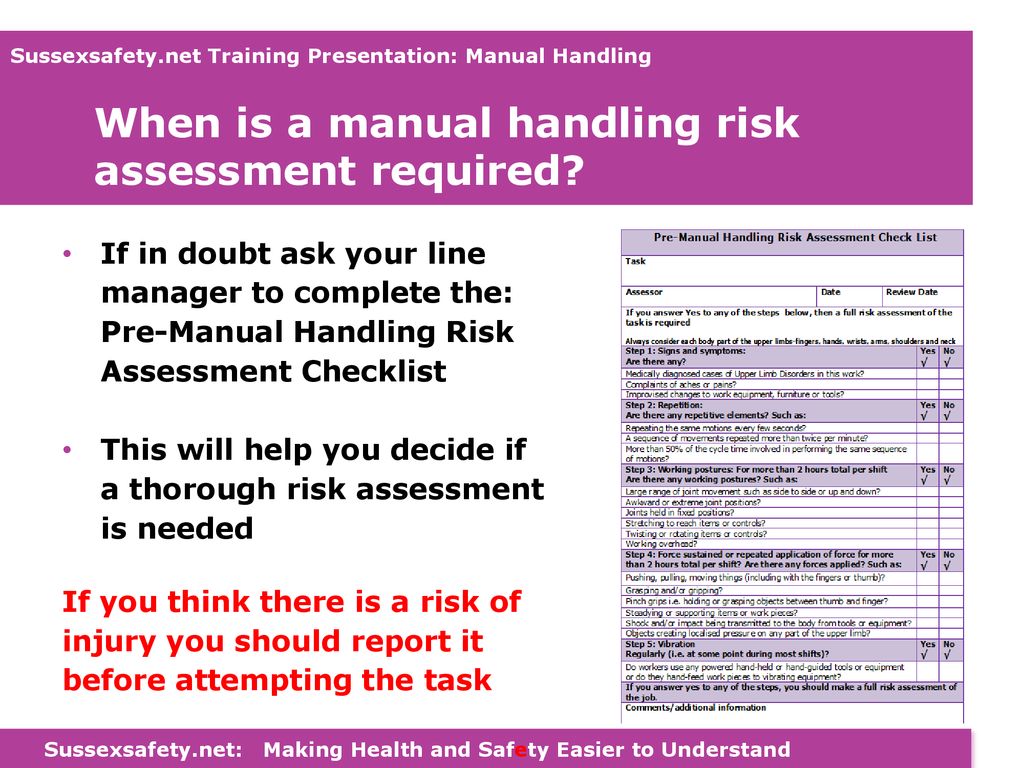

A load can be an object person or animal. Full manual handling risk assessment. Manual handling risk assessments should be performed for each appropriate task in your organisation and reviewed if any part of the process changes. Communicating any potential hazards or risks to your team in a clear way.

Sounds simple enough but when and how often should you review your risk assessments. Lifting and carrying more detailed assessment where necessary questions to consider. There are risks in handling even light loads if the task is repetitive or is being carried out in poor conditions. As an employer it is your responsibility to ensure you are compliant with regulations and that your staff are aware of the safe practices.

Skip to main content. Step 5 of the 5 steps to risk assessment is to review your assessment and update if necessary. If you are not already familiar with the 5 steps to risk assessments check out our blog post what are the 5 steps to risk assessment. As an employer or self employed person you must do a risk assessment but you only need to record it if you employee five or more people.

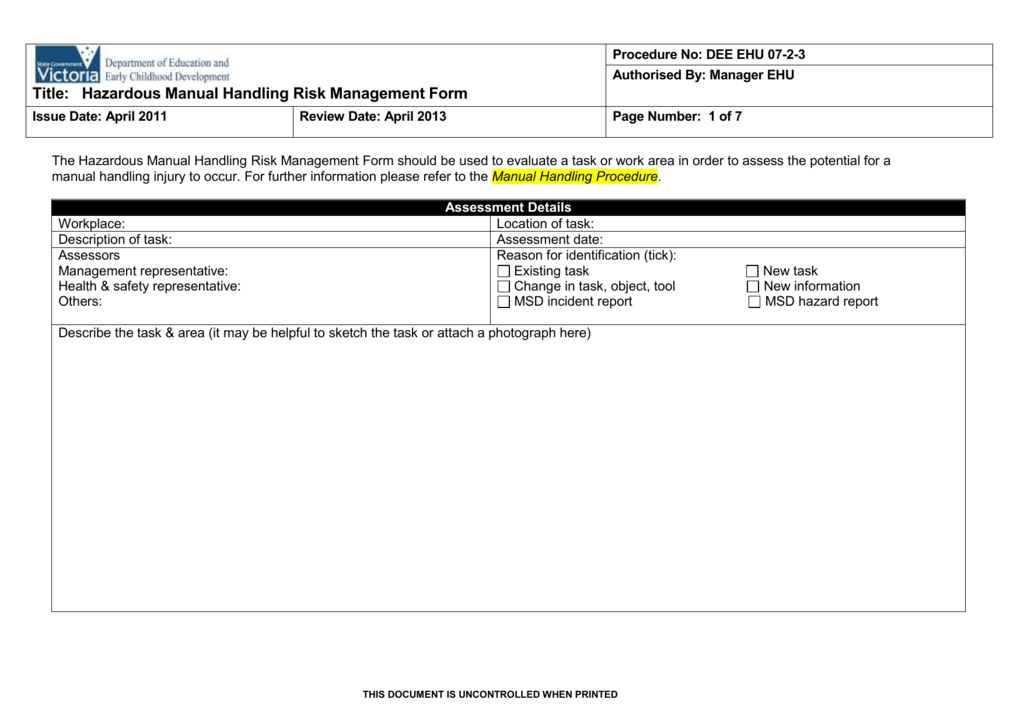

Few workplaces stay the same. Manual handling risk assessment. Our company completed a number of manual handling risk assessments on employees over two years ago. This may include the implementation of safe system of work plans for site specific tasks providing.

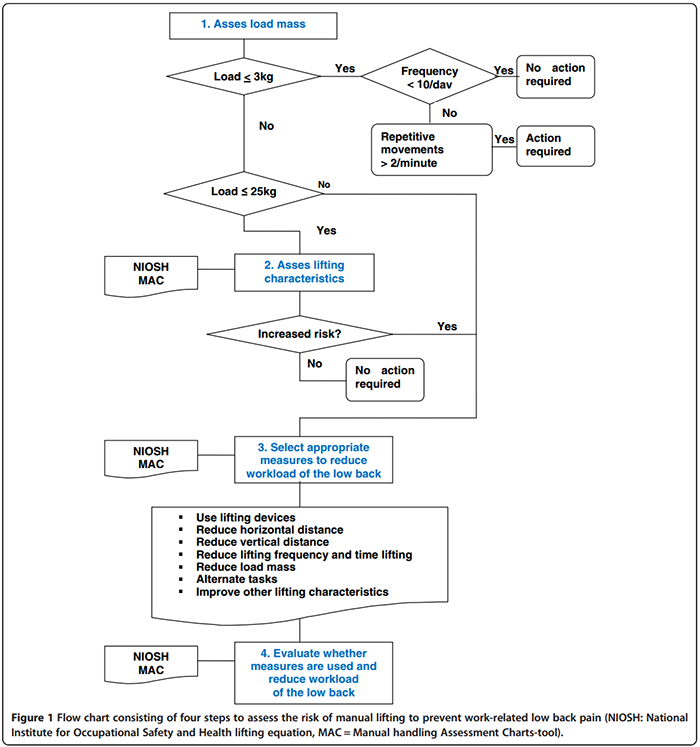

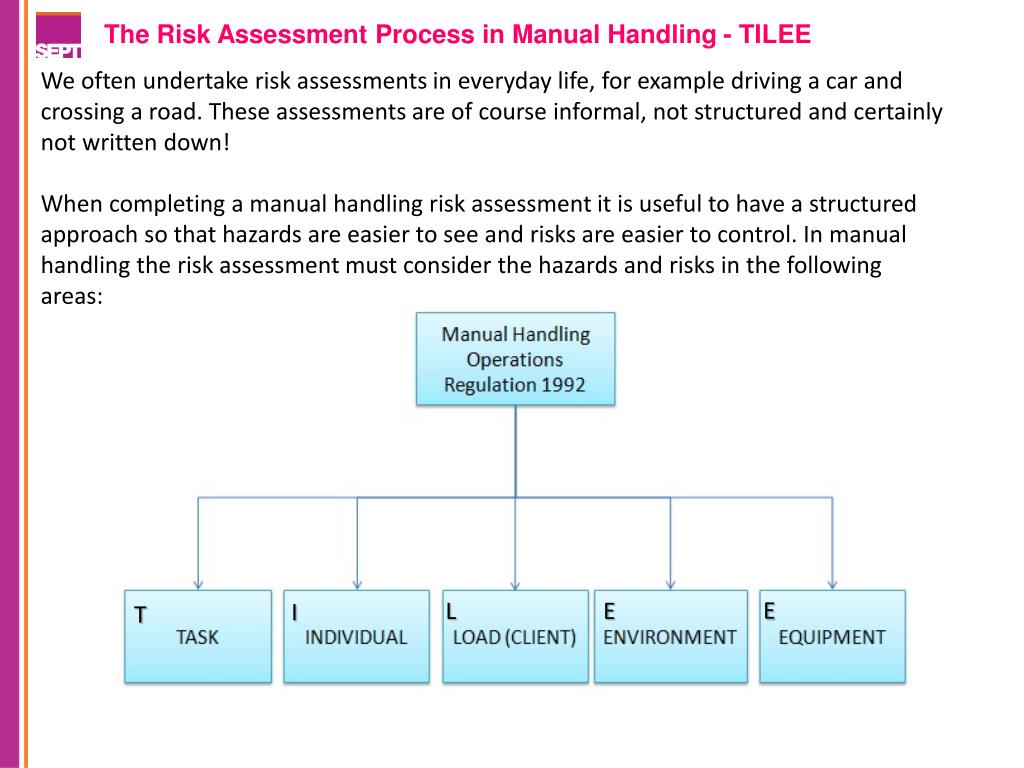

Best practice manual handling best practice is considered to be. To manage the hazard of manual handling through implementation of a manual handling risk assessment process and implementation of preventative measures based on the outcomes of the risk assessments. Monitoring your operational standards on a regular basis. If yes tick appropriate level of risk problems occurring from the task.

In this post we will look at how often you need to review a risk.